SPLICES

Lap splices involve extending existing concrete elements such as beams, slabs, columns, and walls. The new bars are not in contact with existing ones.

In splices, straight post-installed bars are anchored deep into existing elements and ensuring the drill hole remains perpendicular to the surface is the sole challenge. This is overcome by use of specialist accessories like drilling aids. Hilti assists designers in finding feasible and economical solutions for such connections.

Qualification per EAD 330087

Assessment with EAD 330087 establishes equivalence of the adhesive mortar systems to cast-in-place rebars in terms of load-displacement behavior, bond-splitting resistance, and robustness under different installation, environmental, and loading conditions. This EAD is valid for only simply-supported end anchorages and the corresponding ETA provides data for use in design.

Relevant Products: RE 500 V4 & HY 200 R V3

Design of Splices

For lap splices, once the design of the new section and required reinforcement is complete, calculation the anchorage length, lbd, required to transfer the stress in the bar to the existing member is undertaken with the same provisions found in EN 1992-1-1 for cast-in bars.

Additional checks in both instances involve complying with further requirements such as the project design or service life, the minimum anchorage length requirements of EN 1992-1-1, and checks on the shear transfer at the interface of new & existing concrete with Section 6.2.5 of EN 1992-1-1.

Design your connection for demanding conditions

Static Design

This is the most common class of applications for post-installed rebars and includes the connection of new components to an existing structure. According to structural concrete building codes, the bond strength of cast-in bars is limited, even where depth of concrete cover is considerable. And so, in some areas, such as walls where anchorage depth is often limited, welded transverse reinforcement or hooks are used to compensate for the reduction in available anchorage length.

Seismic Design

An increasing population density, the concentration of valuable assets in urban centers and society’s dependence on a functioning infrastructure demand a better understanding of the risks posed by earthquakes. In several areas around the globe, these risks have been reduced through appropriate building codes and state of the art construction practices. The development of pre-qualification methods to evaluate building products for seismic conditions additionally contributes to safer buildings for generations to come.

Fire Design

Organic adhesives are affected by high temperatures. For post-installed rebar connections that are part of a fire-rated assembly (floor, roof, etc.) it is important that the fire resistance of the connection be evaluated using test data for the time-dependent reduction in bond strength associated with typical geometries and time-temperature loading protocols.

Select the right design approach

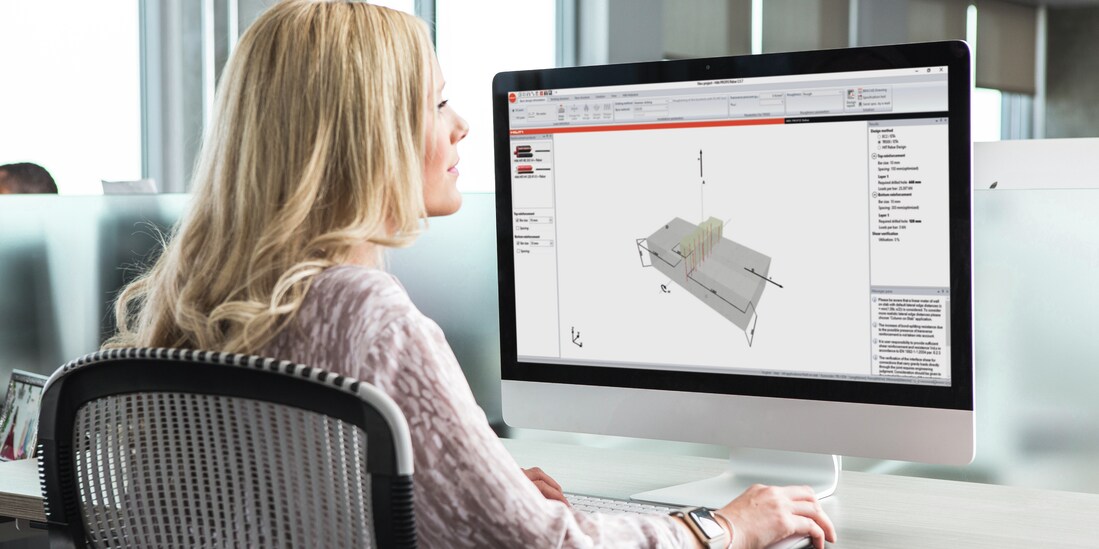

Design with PROFIS Engineering software

Tap into the power of Hilti PROFIS Engineering to:

- Handle large volumes of calculations

- Design with shorter anchorage lengths with Hilti design methods and chemical adhesives

- Design according to Eurocode 2 and EOTA TR069

- Detailed information of all Hilti rebar products and their technical data

- Quickly generate detailed technical reports

Request rebar design from Hilti

Hilti rebar design service to assist you in the design and calculation of your rebar applications with the most optimized solution for you.

Our service includes:

- Cover letter

- Checklist including summary of request and input details

- Detailed bill of material per application

- Complete software calculation report per application

- PROFIS Engineering software design file (.hpr) per application

- Specification text

INSTALL POST-INSTALLED REBAR CORRECTLY

POSITION

Scanning

Scanning of the surface avoids cutting through existing reinforcement and drilling unnecessary holes.

Hitli PS 300 has an integrated display to provide rebar layout visuals in top view and sectional view for on-the-spot structural analysis.

Watch VideoDRILL

Drilling for rebar

Drill faster and safely with Hilti combi-hammers and extra-rugged Hilti hammer drill bits

Hilti TE 30 has Active Torque Control (ATC) stops the tool body from spinning uncontrolledly if the drill bit jams.

Discover moreCLEAN

SafeSet

Inadequately cleaning holes during installation can reduce the performance of chemical anchor systems significantly.

Hilti SAFEST Technology eliminates this factor almost entirely by automatically cleaning the hole while drilling.

INJECT MORTAR

Inject chemical using Piston Plug

Injecting the right amount of chemical is important to ensure that the chemical sets around the rebar o bond with concrete.

With the help of our cordless adhesive anchor dispenser, the right amount of anchor is injected with a single push of a button. You achieve the accuracy you need, while using up to 30% less resin.

Watch VideoSET REBAR

Rebar setting

For easy installation, the rebar must be inserted slowly twisted into the drill hole until the embedment mark. Twisting the rebar, eliminates the air bubbles and ensures chemical is evenly spread around the bar.

Watch VideoProper installation is important to ensure that the post installed rebar behaves as designed. The following installation steps must be followed at the jobsite in the same order to ensure the safety of the rebar connection.